Fabric Laminates - Tufnol SRBF Material - Grade 2F/14

Cotton fabric laminate

Medium weave cotton/phenolic resin laminated plastic

(SRBF – Synthetic resin Bonded Fabric)

Tufnol Grade 2F/14 is a cotton fabric laminate with enhanced electrical properties, specially developed to meet the requirements of the relevant British Standard specification.

The medium weave base cotton fabric is impregnated with phenolic resin to provide enhanced mechanical properties, including rigidity and strength.

What is Grade 2F/14 used for?

Tufnol SRBF (synthetic resin bonded fabric) Grade 2F/14 is used for electro-mechanical applications where the benefits of mechanical toughness and wear resistance are combined with a need for good insulation resistance.

Typical uses of Tufnol SRBF Grade 2F/14 include slot wedges, stator packings, coil formers and operating arms.

Application

- For electromechanical applications.

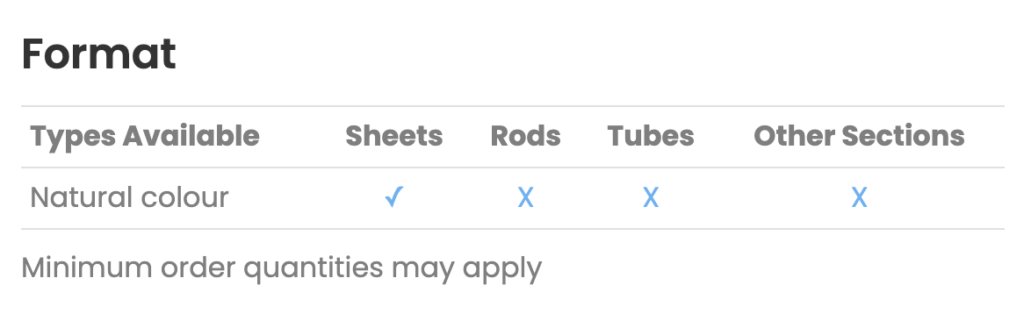

Format

| Types Available | Sheets | Sheet (RFS) | Tubes | Other Sections |

|---|---|---|---|---|

| Natural colour | ✓ | X | X | X |

Minimum order quantities may apply

View/Download Datasheet(s):

Standards

- Sheet: BS EN 60893-3-4 Type PF CC 202

- Rod from Sheet: BS EN 60893-3-4:2012 PF CC 202 & 204