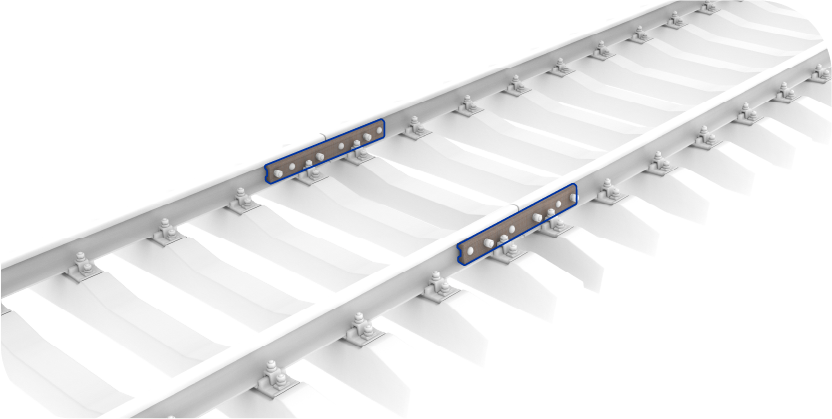

Rail

Tufnol materials and CNC machined components

Harsh, aggressive operating environments require materials that can meet these challenging conditions and provide optimum performance.

It is not surprising therefore that rail engineers around the world look to Tufnol material to cope with the extreme and arduous operating conditions, while at the same time meeting the safety and quality requirements demanded in this industry sector.

A typical application is the bogie pivot pads on railway carriages. These are manufactured from a hard wearing reinforcement of medium weave cotton fabric which utilises an advanced resin system with the addition of PTFE.