Tufnol - Quality Engineering Plastics

Tufnol is at the forefront of engineering composites, laminated composites and resin-based materials for engineering applications.

Our reliability at Tufnol is legendary. It is based on:

- Fast, efficient service for materials and machined components

- Comprehensive technical capability

- Top quality materials and machined parts from one UK source

- Over 90 years’ experience as leader of the laminated composites, resin materials and composites industry

- Quality System Management registered to AS 9100 Revision D and ISO 9001:2015

- Many supplier quality accreditations and approvals

- Signatory to SC 21, the British aerospace industry’s programme promoting Supply Chain

- Excellence in the 21st century

A comprehensive research and development programme

We ordered some large Tufnol blocks in Bear brand as well as 630 washers from 6mm Bear brand for our project. The idea is that these blocks are used to protect goods from the wharf. When goods travel up and down the wharf and if they move off-line, they will hit the blocks, instead of any other stationary or moving objects. We were very impressed with the quality of the machining, so much so the Quality Manager commented on the precision of the saw work! We have some other similar projects that we are keen to start on, developing from the way this project has performed.

CE&A Marine Engineering

Quality Management at Tufnol Composites Ltd

Development of laminated plastics

Back in the 1920’s engineering laminated composites originally grew out of the electrical industry’s need for high performance insulation materials with consistent and reliable performance. Even today, in many countries around the world, laminates are thought of primarily as materials for the electrical engineer. Tufnol is renowned for providing insulating materials for everything from high-end electronics to all sorts of large electrical machines.

Mechanical applications of laminates

Right from the early days, Tufnol laminates were also eagerly adopted for mechanical applications by the aircraft and automotive industries. Engineers designing and building aircraft found the longevity of Tufnol, and its consistent high strength and light weight ideal for all sorts of uses in aeroplanes wherever a non-metallic material was needed.

Today, aerospace and top-end automotive companies remain a large and important proportion of our customers.

Quality assurance systems for engineering plastics and composites

Quality assurance systems at Tufnol have, for many years, been subjected to scrutiny and approval by a number of independent authorities and government bodies, and the appropriate approvals gained. Today, Tufnol’s quality assurance systems have become an integral part of our culture. Tufnol Composites Ltd holds registration to Aerospace Quality Standard AS 9100 Revision D.

DEMS is proudly the sole Importers and distributor for the internationally renowned Tufnol UK range of Laminates and composites in South Africa. Our customers choose Tufnol materials due to its high strength and long-lasting properties for all kinds of engineering applications from transportation to heavy machinery. The high-performance credentials of Tufnol laminates and composites make it the perfect solution for demanding environments.

DEMS

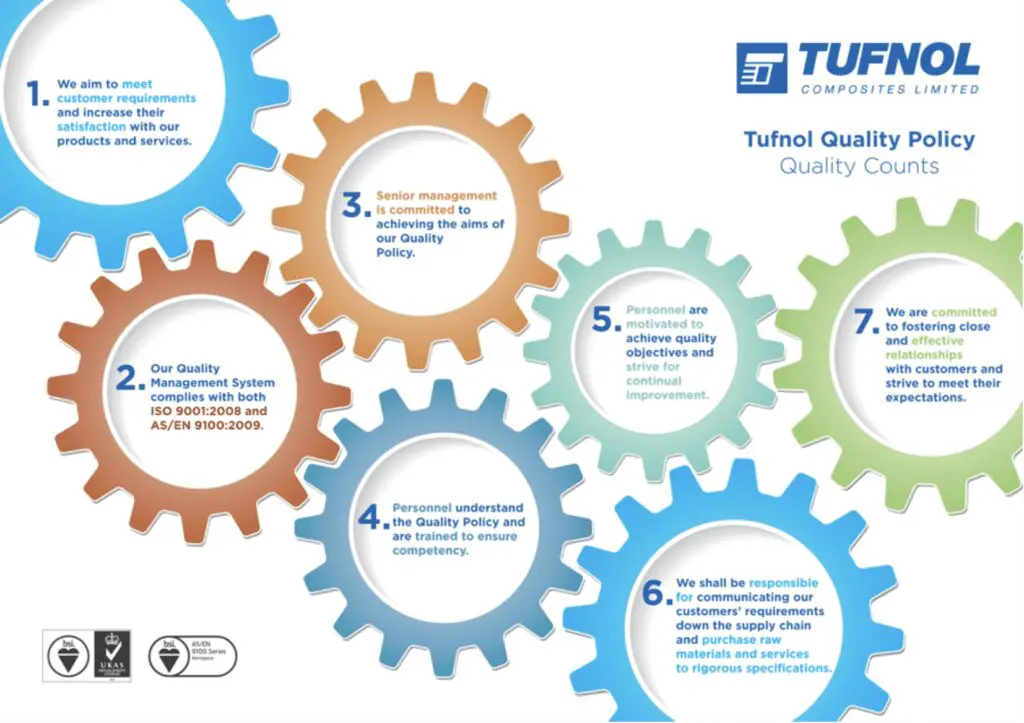

Quality Pledge

- We aim to meet customer requirements and increase their satisfaction with our products and services

- Our Quality Management System complies with both ISO 9001:2015 and AS/EN 9100 Rev D.

- Senior management is committed to achieving the aims of our Quality Policy

- Personnel understand the Quality Policy and are trained to ensure competency

- Personnel are motivated to achieve quality objectives and strive for continual improvement

- Tufnol will be responsible for communicating their customers’ requirements down the supply chain and purchase raw materials and services to rigorous specifications

- Tufnol are committed to fostering close and effective relationships with customers and to strive to meet their expectations