Tufnol SRBF Bearings - Cotton Fabric Laminates

Wide range of uses

Tufnol cotton fabric bearing materials are widely used where tough, wear resistant components are needed. They give good service under a very wide range of operating conditions, including continuous temperatures from cryogenic levels to well over 100°C and in a wide variety of situations where resistance to corrosion is needed.

Lubricated is better

Although Tufnol laminates are used dry in many less demanding applications, most Tufnol cotton fabric bearing materials are not self lubricating and it is preferable to use a lubricant to develop their full bearing potential. Properly designed and lubricated Tufnol bearing surfaces give excellent service for many years and are frequently a most cost effective choice.

Lubricate with water

The ability of Tufnol materials to be effectively lubricated with water is particularly useful. In many applications, design has been simplified and cost reduced because the Tufnol bearing could be lubricated by the fluid in which it was operating, eliminating the need for sealed bearings with oil or grease inside.

Use cotton fabric grades

The cotton fabric grades are most commonly selected for wearing and bearing applications up to about 120°C. As with all applications, the final selection of grade should be based on a broad understanding of the requirements of the job, including such factors as temperature, pressure, velocity, shock loading, lubrication, and the degree to which the bearing will be expected to tolerate detrimental factors, such as deterioration of working environment during its life.

Chemical Resistant

Dry bearings when you need them. For cases where a material is required for a dry bearing application, one particular grade of Tufnol is offered which does have self lubrication capabilities. Tufnol Grade 2F/3/PTFE is a cotton fabric laminate which contains finely divided particles of PTFE powder distributed throughout the material. This combines the mechanical strength, rigidity and toughness of a laminate with the self lubricating and low friction characteristics of PTFE.

Acid/Alkalis Resistant

. . . and other plastics. In addition, where required, Tufnol Composites Ltd can offer a wide range of other engineering plastics such as nylon, polyacetal, PETP and polyethylene and will be happy to give advice on material.

Designing Tufnol Bearings

Fixing Methods

Although press fitting is the most commonly used fixing method for small cylindrical bearings, when temperature and moisture content are likely to vary widely in service, it is inadvisable to rely solely on an interference fit and some form of mechanical fixing is then preferred. In fact, where a cylindrical bearing is required with minimum initial clearance, positive fixing is usually recommended, as this allows closer control without machining in-situ. Typical fixing methods include keys, set screws, pegs, and flanges with screws or adhesive bonding. However, it is important not to use a method such as grub screws which can distort the shape of the bearing and cause binding on the shaft.

Flanged Bearings

Flanges required for location purposes can be provided in several ways. If the required flange diameter is a little greater than the outside diameter of the bush itself, it is usual to produce the flanged bush in one piece from oversized material. However, for greater flange diameters, this would involve greater wastage of material and therefore fabricated components are generally preferred. In such cases, the flange is produced from Tufnol sheet material and a step is machined on the outside diameter of the bush (see Figure 2). The flange is then bonded on to the end of the bush, using a high strength epoxy adhesive.

In the majority of cases, this is perfectly adequate, but where very arduous duty is anticipated, an even stronger flange joint can be achieved by machining screw threads in both Tufnol components and screwing the flange on to the bush after coating the threads with epoxy adhesive. Flanges produced from sheet material offer maximum compressive strength, in view of their more suitable direction of laminar structure and bushes with fabricated flanges are therefore very successful.

Interference fitting. Where bearings are to be press fitted, the dimensions should be calculated in line with the recommendations given below, taking care to allow adequately for closure of the bore due to the interference of the outside diameter. The bush or housing should be made with a lead chamfer to avoid damage to the bush while it is being pressed in.

Slideways

Dimensional movement may also need to be catered for when designing slideways or wear strips. Although the dimensional movement of a laminate is proportionally much less in the plane of the laminations than through the layers, long slideways should not be just fixed at the ends or dimensional movement can cause buckling. Wear strips would typically be held every 100 to 150mm along their length by screws or rivets with heads recessed well below the surface.

Bearing Design in Tufnol Laminates

Performance

Bearing performance. Many factors influence the performance of a bearing. Pressure, rubbing speed, surface finish, temperature and lubrication all contribute and a change in one of these can often cause changes in one or more of the others. This makes precise prediction of friction and wear extremely complex.

PV Factors for dry bearings. To assess suitability of a dry bearing, a common approach is to simplify the problem by considering the PV factor of the bearing. The PV factor for a particular application is obtained by multiplying the working pressure by the velocity. This is then compared to a maximum PV factor for the material. This maximum PV factor is derived from experimental data recorded over a range of conditions and it is usually also adjusted for different conditions of ambient temperature and humidity.

PV factor limitations for lubricated bearings. For properly designed and operated dry bearings, PV factors provides a very useful rule-of-thumb assessment but when a lubricant is introduced, a whole new set of factors come into effect. In well lubricated bearings, very high PV factors can be tolerated and this simplified approach to performance assessment becomes unworkable.

Working temperature – a crucial factor. Operating temperature is important in many plastics applications and with dry bearings in particular it is often the factor which limits performance.

This is especially true of thermoplastics bearings, where load capacity depends on the temperature rise and the allowable degree of deformation at the working temperature. This is less applicable to laminated plastics bearings, which do not creep appreciably at normal working loads but it is, of course, still important to keep the operating temperature well within the capabilities of the material.

At high loads and speeds, the cooling function of a lubricant becomes especially important and, in some applications, it is not uncommon to obtain very high bearing performance by circulating lubricant through the bearing under pressure.

Bearing Design – General Principles

Dimensions and allowances. Design of Tufnol bearings follows conventional engineering practice and in many cases Tufnol laminates can be used to replace another material. A length to shaft diameter ratio of 1:1 is considered generally ideal because long bearings (over 2:1) can contribute to the build-up of heat, which is the main enemy of plastic bearings. Allowance should be made for the dimensional movement which can take place due to changes in the temperature and moisture content of the material.

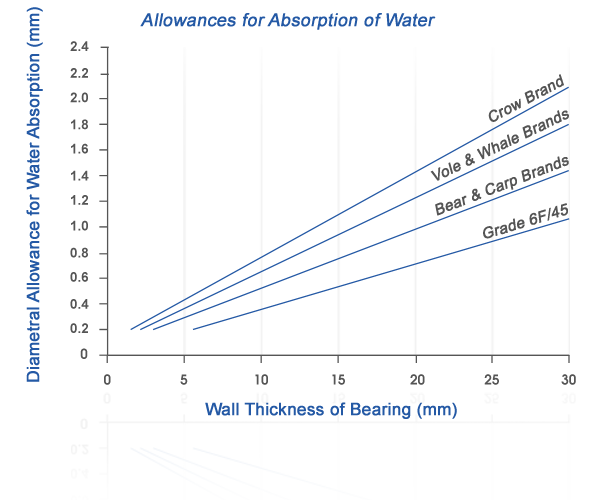

Laminates are able to absorb a small amount of water and, when they do, slight dimensional changes take place. These changes are predictable and it is essential that the initial clearances in a bearing allow for this dimensional change in line with the recommendations given in Table 1 below. See also Figure 1.

Table – Dimensional Stability

| Increase in dimensions after prolonged immersion | ||

|---|---|---|

| Tufnol Grade | in plane of laminations | normal to plane of laminations |

| Bear Brand, Carp Brand | 0.30% | 2.5% |

| Whale Brand, Vole Brand, Grade 2F/14 | 0.35% | 3.0% |

| Crow Brand, Grade 2F/3/PTFE | 0.40% | 3.5% |

| Grade 6F/45 | 0.20% | 1.7% |

Figure 1. Allowances for absorption of water.

The housing should be designed so that the TUFNOL material is fully supported and any grooves which are included should not excessively weaken the wall of the bearing.

As a general rule of thumb, groove depth should not exceed one third of the wall thickness. Normally, to assist heat dissipation, excessive wall thicknesses are to be avoided but, where high shock loads are expected, an increased thickness of bearing material is usually preferred.

Lubrication

The type of lubrication chosen to suit the application may range from none at all, or perhaps a slight smear of grease on assembly, up to a fully designed circulating system with copious supplies of filtered lubricant pumped under pressure.

Most of the common lubricating oils and greases are suitable for use with Tufnol. Water is also an excellent lubricant, as are many water based fluids, provided that they are not chemically corrosive and do not contain abrasive solids. Many examples exist of Tufnol bearings successfully lubricated by process fluids such as inks, dyes, cleaning fluids, metal treatment solutions, effluents, coolants and the like.

Where necessary, arrangements should be made to exclude dirt or abrasive matter from the rubbing surfaces. For example, where a bearing is lubricated with river or sea water, any sand or silt should be filtered out before the water enters the bearing.

Grooves are used to help distribute lubricant, and can also be beneficial in providing an escape route for any dirt or wear debris which could otherwise accumulate. Generally, it is preferable to design grooves in simple shapes for even distribution of lubricant, as complex patterns are not required. Obviously, grooves should not be placed in the most heavily loaded areas of the bearing, and should not interfere with the beneficial build up of lubricant pressure between bearing, and shaft under hydrodynamic conditions.

Mating Surfaces

For optimum performance, a hard smooth mating surface is preferred. Surface finishes in the range of 0.4 to 0.8µm CLA are commonly accepted and mating materials such as hardened steel, hard chrome plated or stainless steels or gun metal are often used. Surface hardness better than Rockwell C50 is usually considered ideal but Tufnol laminates are reasonably tolerant and softer shaft materials have given good service in a great many bearings where the loads and speeds were not exceptionally high.

In some cases, mating materials made from other plastics have been used. Whilst this may be acceptable for special purposes, heat dissipation from the rubbing surfaces is restricted and it is not an ideal arrangement.

Calculating Bearing Dimensions: