How does the battery work?

The main setup of the University of Liverpool car’s High-voltage Battery is multiple modules which are monitored and charged through various electrical components so the measurements and safety of what is going on can be seen, to ensure the system is running as it is meant to. The main electrical components include a BMS (Battery Management System) and IMD which help to manage and monitor the electrical flow in the system. This monitoring includes Voltage and Temperature.

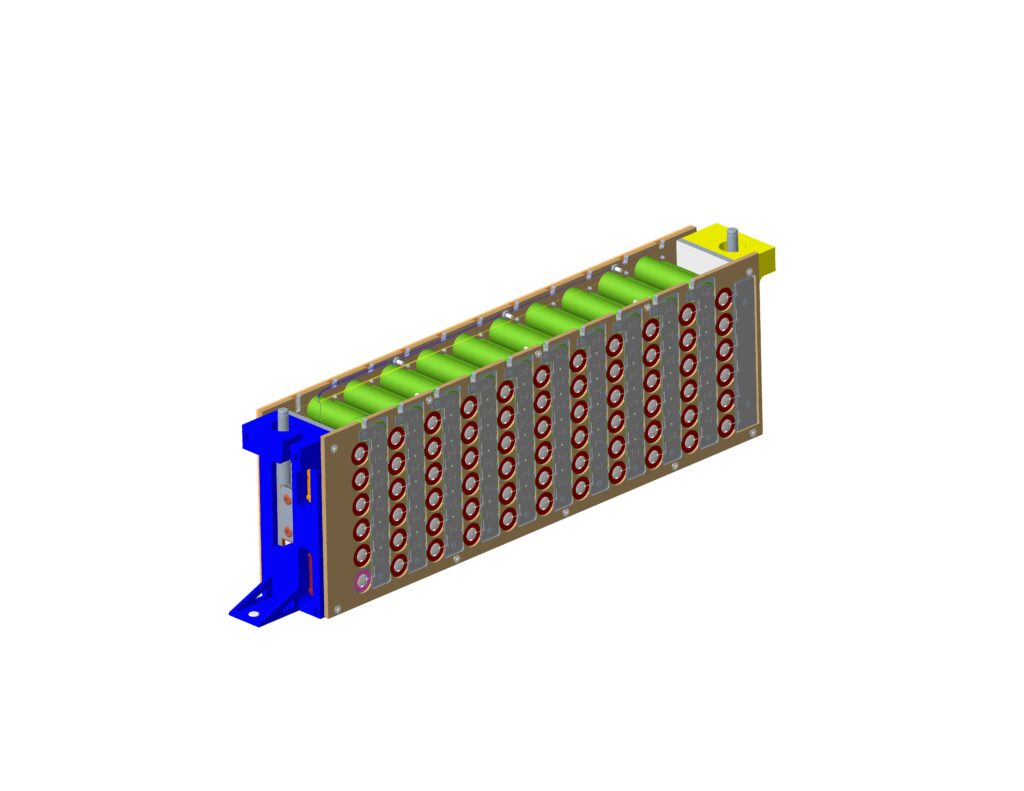

As the modules contain the cells, the main electrical capacity and mass of the battery, they must be electrically and structurally effective.